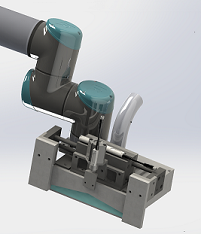

This robotic solution is one of the latest R&D developments made by IRUÑA AUTOMATION.

The new solution allows the automatic application of adhesive beads in the different joints of the wind blades: Webs & Shells, Leading & Trailing edges of the shells, etc. The robotic solution can be used too in other sectors or applications.

The robotic solution includes a vision system to identify the exact location of the adhesive bead; and an adhesive applying head, which allows the modification in size and shape of the bead, if needed. This functionality avoids application stops to change the adhesive applying heads along the blade.

The robot can be moved along different parts of the blade, using a gantry system or over an AGV. Additionaly, the solution can include a scan system, as an optional, to check the final shape and location of the adhesive bead after its application.

Thanks to this new solution, wind blades manufacturer can improve significantly workers’ HSE, reduce to lower cycle times and obtain higher quality, reliability and traceability in their adhesive applying process.

All of these factors allow to achieve a reduction in possible non-quality costs derived from gluing defects.

For more information, please contact us through our web page.

turn key project. Custom-design application

Comentarios

No Comments